|

Thermal transfer printing machine DETAILS

Equipment features: Infrared correction function of fabric and felt; Double release and double collection, reduce the time of material replacement; Speed and effect are reflected in time; Pneumatic constant tension system; Start up and shut down for a long time; International brands and imported electrical supporting solutions, but also customized according to customer needs for their own equipment; Automatic unloading function, simple operation; The whole machine is highly automatic and easy to operate; Equipment introduction: This high-speed printing machine is tailor-made for customers with a number of industrial high-speed inkjet machines. It is also suitable for customers with a large number of intaglio business. The new design of this equipment is different from the domestic conventional "transfer printing equipment". The company's almost harsh requirements explain the new working mode of this equipment. The equipment is born in the era of digital printing industrialization, and also meets the stable demand of transfer printing production. The simple and clear PLC control interface and stable manufacturing process of the original roller make the heating roller work safely and stably on the equipment, so that there will be stable output of high-quality products. The output is better than the domestic equipment of the same size, with lower energy consumption and better transfer effect. The convenient loading and lifting device can control the loading and unloading of materials effectively and easily. The water cooling device makes the fabric cool quickly, avoids the stretch of elastic fabric and reduces waste. It can also be customized according to the customer's opinions, combined with the supporting company's "printing solution".

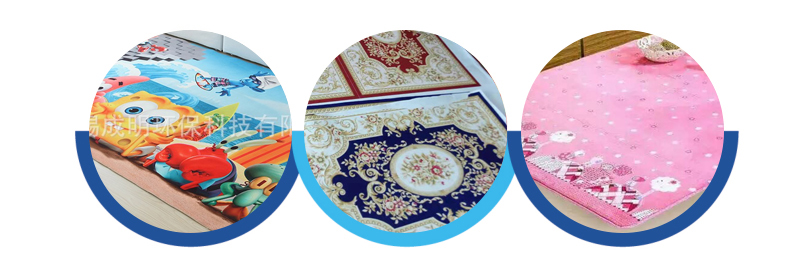

Applicable objects It is suitable for mass production of cloth or digital printing in garment factories. The process is simple, environmental friendly and pollution-free No need for sizing and soaping. Cooking. Setting and other processes, can directly print grey cloth, after printing into the tunnel furnace, out is the finished product, the production process does not produce waste water and waste gas, safety and environmental protection without pollution. Strong applicability and stability Transfer width: 0.6-3.2m, unlimited transfer length, continuous batch production, unlimited time. Fast transfer speed The printing speed of the machine depends on the gram weight of the paper and the weight of the PIP, about 0-800 meters per hour. No fading, soft feel Water washing, sun exposure and wet grinding. Dry grinding does not fade, can reach 4-4.5 color fastness, some fabrics even up to about 5. Sample display

|